Use this setting to achieve the desired hydraulic circuit temperature using two or more boilers connected in cascade.

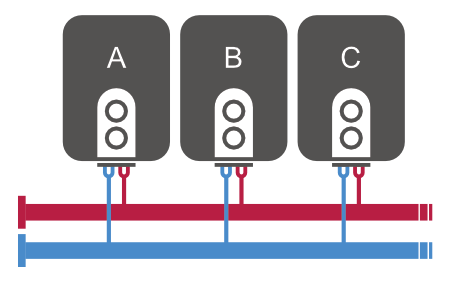

In the example scenario, we will show the configuration for 3 boilers that can be controlled by digital outputs.

Preparation

You should already have the following devices defined:

- Thermostat with return water temperature measurement on the pipe

Digital outputs for each boiler

- Boiler A

- Boiler B

- Boiler C

Virtual analog output

This output will be used as a variable to calculate the total heat output.

Basic configuration

Create a Smart Rule PID temperature controller that will calculate the total output based on the difference between the thermostat setpoint and the current temperature.

| Input device | → Smart Rule → | Output device |

|---|---|---|

| Thermostat | → PID Controller → P = 2, I = 0.2, D = 0 | Total output |

Based on the range of the total output, 3 (or more) boilers will be turned on.

Configuration for the mode where boiler priority is: Boiler A → Boiler B → Boiler C

| Input device | → Smart Rule → Equation | Output device |

|---|---|---|

| <1% | – | – |

| >1% | If the total output > 0.01 Minimum duration: 5 min TRUE: Turn on Boiler A FALSE: Turn off Boiler A | Boiler A |

| >45% | If the total output > 0.45 Minimum duration: 5 min | Boiler B |

| >90% | If the total output > 0.90 Minimum duration: 5 min | Boiler C |

Boiler rotation

To ensure even use of the boilers, additional configuration is required.

Creating a multi-valued switch

Define N+1 states, where N is the number of boilers.

The last state can be defined as Heating inactive, which means the system is not heating.

Name: Boiler Priority

States:

- Priority A (Boiler A → Boiler B → Boiler C)

- Priority B (Boiler B → Boiler C → Boiler A)

- Priority C (Boiler C → Boiler A → Boiler B)

- Heating inactive

Creating a Smart Rule sequencer

This sequencer will rotate priorities as follows:

A → B → C → A → …

| Input device | → Smart Rule → | Output device |

|---|---|---|

| Virtual button to start the sequencer | Sequencer | Boiler priority |

| Step 1: Priority A (duration: 18 hours) | ||

| Step 2: Priority B (duration: 18 hours) | ||

| Step 3: Priority C (duration: 18 hours) | ||

| ✅ Rotate sequence |

Define a separate set of Smart Rule rules restricted to each boiler priority.

See Smart Rules for Priority A in the table below:

| Input device | → Smart Rule → Equation | Output device | Restricting condition |

|---|---|---|---|

| <1% | – | – | – |

| >1% | If the total output > 0.01 TRUE: Turn on Boiler A FALSE: Turn off Boiler A | Boiler A | Type: Multi-valued switch Rule only applies when Boiler Priority is set to Priority A |

| >45% | If the total output > 0.45 TRUE: Turn on Boiler B FALSE: Turn off Boiler B | Boiler B | Type: Multi-valued switch Rule only applies when Boiler Priority is set to Priority A |

| >90% | If the total output > 0.90 TRUE: Turn on Boiler C FALSE: Turn off Boiler C | Boiler C | Type: Multi-valued switch Rule only applies when Boiler Priority is set to Priority A |

A similar set of Smart Rule rules should be applied with a restricting condition for Priority B and Priority C.